Laser cutting

Precision technology for modern manufacturing

Laser cutting

Laser cutting: How it works and key technologies

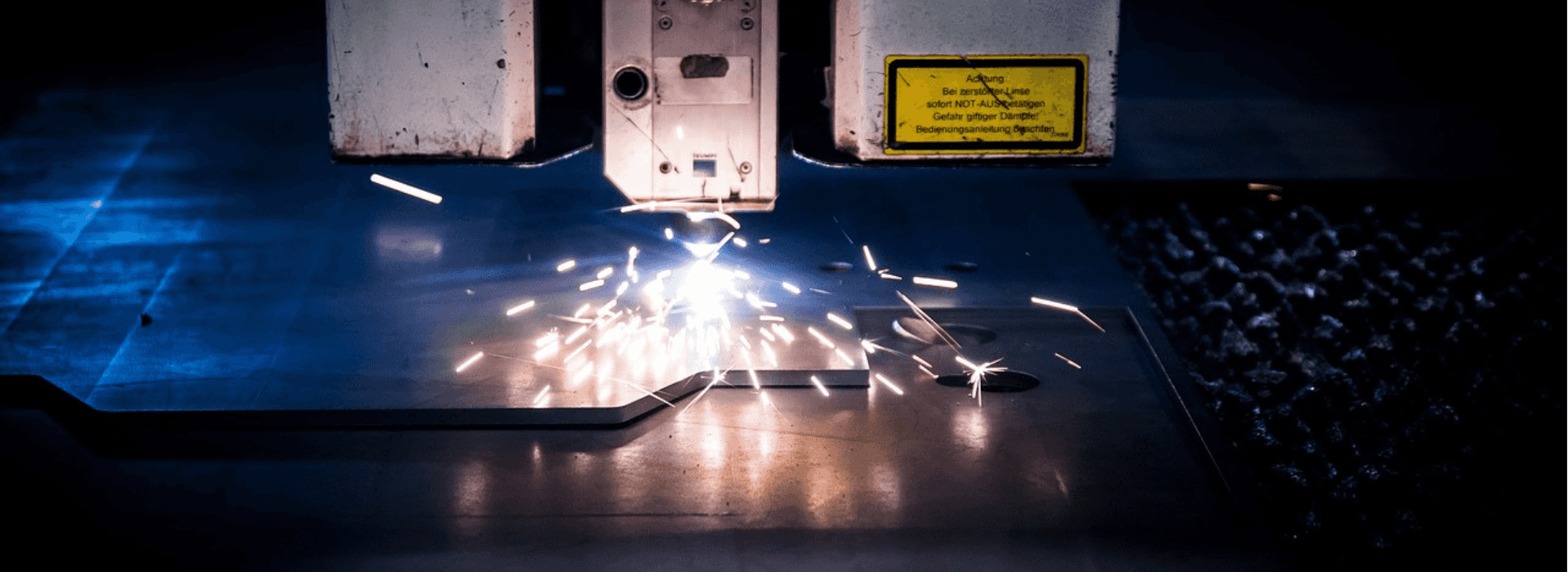

Laser cutting is a precise and efficient manufacturing process in which a highly focused laser beam cuts materials such as metal, plastic or wood. In laser cutting, a laser beam is generated that is directed through optical components, such as mirrors and lenses, to focus the laser beam on a very small focus. The beam melts, burns or evaporates the material through the supplied energy, creating a precise cut is created, which at the same time has a high heat intensity. With laser cutting, complex shapes and fine details can be implemented. For this reason, laser cutting is often used in industries such as the construction industry, plant engineering and mechanical engineering.

Laser cutting - advantages & procedures

Laser cutting: Efficiency and methodology in focus

Advantages of laser cutting at Line Up

Laser cutting

CO2 laser cutting

CO2 laser cutting uses a gas mixture consisting mostly of carbon dioxide to generate a laser beam. CO2 laser cutting is particularly effective for cutting non-metals and metals up to medium thicknesses.

Fiber laser cutting

Fiber laser cutting uses glass fibers enriched with a doped material to generate the laser beam. Fiber laser cutting is particularly suitable for cutting metals and offers advantages in processing reflective materials. In addition, fiber laser cutting is characterized by high cutting speeds.

Metal processing - Inquiry

Line Up: Start your procurement process now

Make an inquiry

Receive offer

Place order

Receive products

Other manufacturing processes of metal processing

Realize your products with the metal processing of Line Up

Contact

Ready to Line Up?

Contact us!

Personally there for you throughout Europe and in China. When will you become one of our satisfied customers?