Waterjet cutting

Waterjet cutting: Precise cuts for a variety of materials

Waterjet cutting

Waterjet cutting: Technology and applications

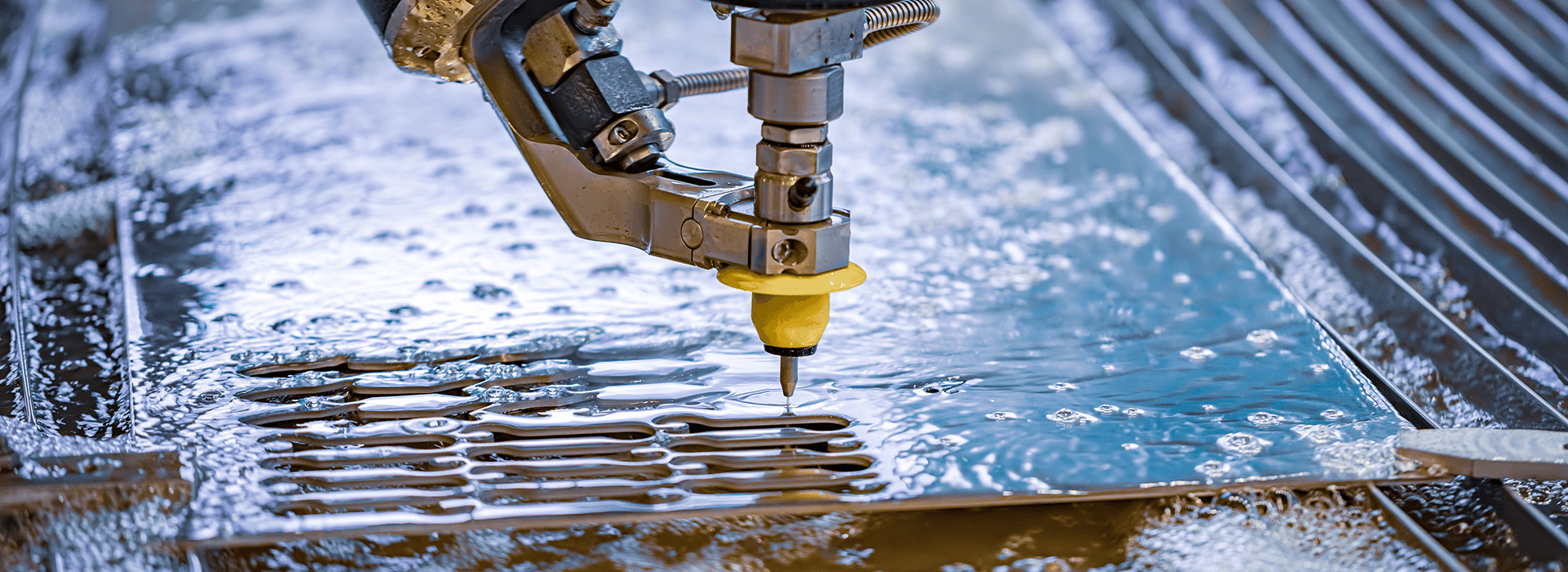

Waterjet cutting uses a high-pressure water jet to cut materials such as metal, stone, glass and plastics. The jet, which is generated under high pressure, is guided through a nozzle head and removes the material. Waterjet cutting is versatile and allows precise cuts without heat development, which is particularly suitable for sensitive materials is suitable. Waterjet cutting fundamentally differs in two different types: pure waterjet cutting and abrasive waterjet cutting. Both techniques use the power of water to cut materials precisely, but differ in their specific applications and the types of materials they cut effectively can cut effectively. This waterjet cutting is often used in the construction industry, plant engineering and mechanical engineering.

Waterjet cutting - advantages & procedures

Waterjet cutting: Benefits and application techniques

Advantages of waterjet cutting at Line Up

Waterjet cutting

Pure waterjet cutting

As the name suggests, pure waterjet cutting works exclusively with water to cut the material under very high pressure. The water is pressed through a very small nozzle to create a concentrated water jet. Pure waterjet cutting operates at a pressure of up to 60,000 PSI, which is about 4,137 bar. Pure waterjet cutting is ideal for soft materials that could be damaged by abrasive waterjet cutting. These include rubber, foam, textiles, paper and thin plastics. Pure waterjet cutting is particularly used in industries that require a very fine and precise cutting edge without subjecting the material to thermal or mechanical stress.

Abrasive waterjet cutting

Abrasive waterjet cutting adds an abrasive material such as garnet sand. This allows abrasive waterjet cutting to cut harder materials such as metals, stone, ceramics, thicker plastics or glass. The abrasive material is added to the water jet in the cutting head and accelerated through the nozzle together. This technique significantly expands the versatility of waterjet cutting. Abrasive waterjet cutting has overall similar properties to pure waterjet cutting and allows very fine and precise cutting edges without subjecting the workpiece to mechanical or thermal stresses.

Metal processing - Inquiry

Line Up: Start your procurement process now

Make an inquiry

Receive offer

Place order

Receive products

Other manufacturing processes of metal processing

Realize your products with the metal processing of Line Up

Contact

Ready to Line Up?

Contact us!

Personally there for you throughout Europe and in China. When will you become one of our satisfied customers?