CNC manufacturing

CNC manufacturing: precision, efficiency and variety

CNC manufacturing

CNC manufacturing: How it works

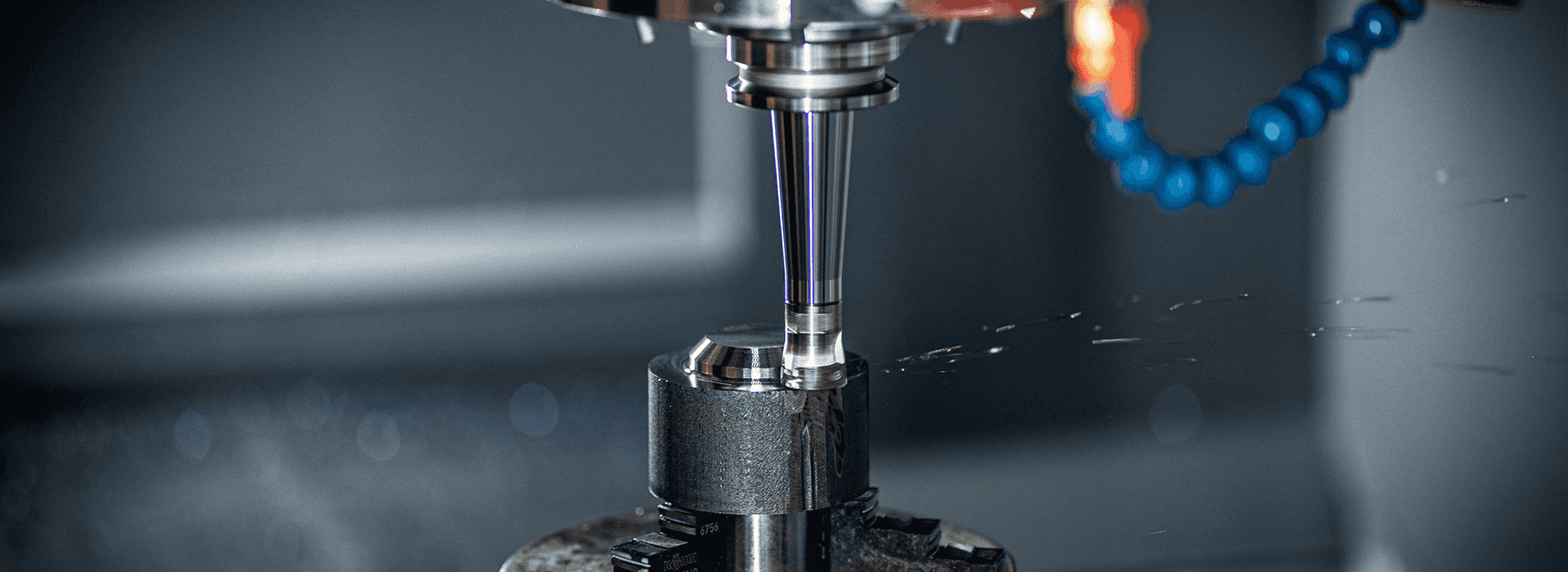

CNC manufacturing is a highly precise manufacturing process, in which computer-controlled CNC machines bring the workpieces into the desired shape by removing material. With a CNC machine, complex shapes with high accuracy and repeatability can be produced. In addition, a CNC machine is able to accommodate various tools for milling, turning or drilling and apply them automatically to the workpiece.

For CNC manufacturing, the design of the part is usually required in the form of a CAD file, which is then converted into a CNC program. The shaping CNC manufacturing processes include CNC milling, CNC turning and CNC drilling.

We offer you manufacturing on state-of-the-art CNC machines with up to 5 axes.

CNC manufacturing - advantages & processes

CNC manufacturing: An overview of its practice

Advantages of CNC manufacturing at Line Up

CNC procedures

CNC milling

CNC milling is a versatile machining process in which a rotating tool, the milling cutter, removes material from a workpiece. CNC milling can produce complex shapes and surfaces. CNC milling machines can also be moved in multiple axes. There are a variety of milling tools, including end mills, face mills and ball head mills, each optimized for different machining tasks such as finishing, roughing, contour milling and thread milling. The ability to create precise contours and details makes milling an indispensable process in modern manufacturing.

CNC turning

CNC turning is a chip-removing manufacturing process that is typically performed on CNC lathes. Particularly cylindrical parts can be produced in this way. The workpiece rotates around an axis while a stationary cutting tool, the turning tool, removes material to achieve the desired shape and size. Turning tools vary in shape, size and application, such as thread cutting. The precision and efficiency of CNC turning make it possible to produce complex shapes and surfaces with high accuracy.

CNC drilling

CNC drilling is a basic CNC machining process in which cylindrical holes are drilled into a workpiece. This is done with a twist drill that rotates and penetrates the material to create the hole. For special requirements for hole quality and shape, additional tools such as countersinks for deburring or expanding the hole edge and reamers for improving surface quality and precision of the hole diameter can be used. CNC drilling allows for high precision in hole placement and size, which is critical for maintaining strict tolerances in manufacturing.

Metal processing - Inquiry

Line Up: Start your procurement process now

Make an inquiry

Receive offer

Place order

Receive products

Other manufacturing processes of metal processing

Realize your products with the metal processing of Line Up

Contact

Ready to Line Up?

Contact us!

Personally there for you throughout Europe and in China. When will you become one of our satisfied customers?