Plasma cutting

Plasma cutting: A deep dive into the modern cutting process

Plasma cutting

Plasma cutting: Core concepts and applications

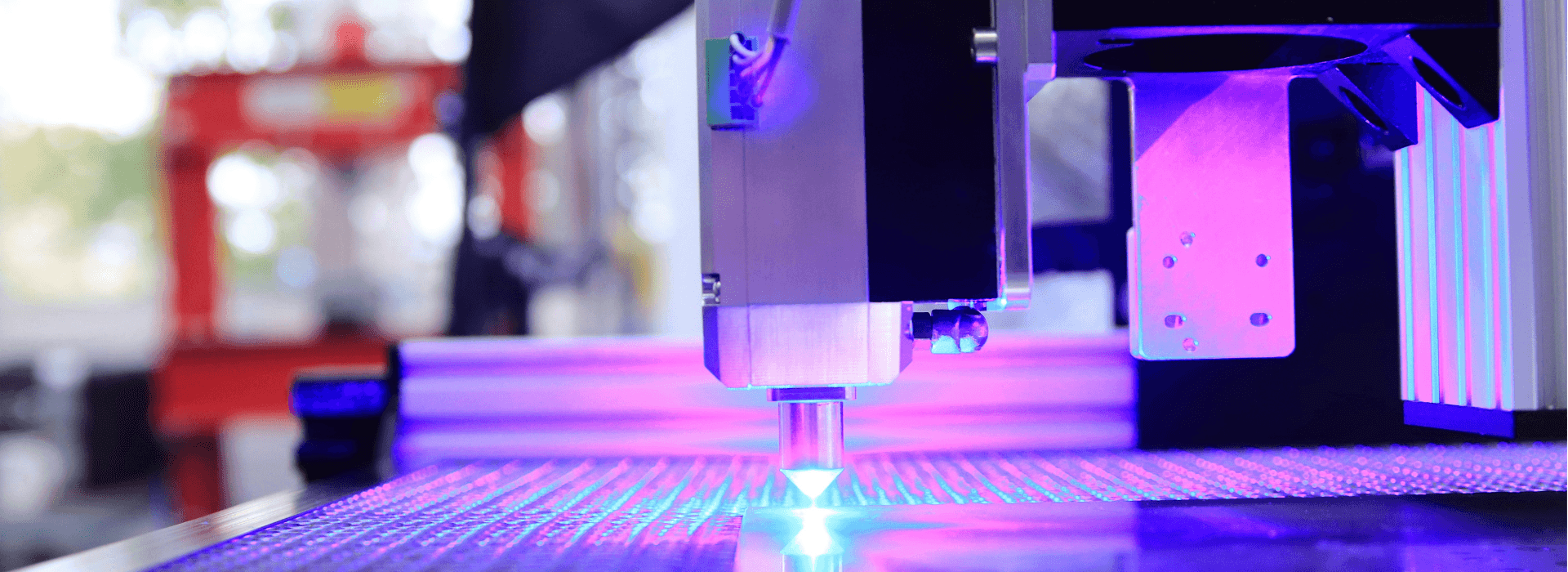

Plasma cutting is a thermal manufacturing process that is mainly used in metal processing. By ionizing a gas, the so-called plasma, a plasma jet is created that melts the metal while an air flow simultaneously removes the molten material. This cost-effective technology is particularly suitable for thick metal sheets and is often used in the metal processing industry and mechanical engineering. Unlike waterjet cutting, plasma cutting exposes the workpiece to high heat and thus to thermal stress.

Plasma cutting - advantages & procedures

Plasma cutting: Benefits and implementation techniques

Advantages of plasma cutting at Line Up

Plasma cutting

Conventional plasma cutting

In conventional plasma cutting, the metal is melted by the so-called plasma while a compressed gas stream simultaneously blows the molten material out of the cut. Conventional plasma cutting is particularly suitable for thicker metal plates and is characterized by a high cutting speed.

High-precision plasma cutting

High-precision plasma cutting is based on conventional plasma cutting and is an advancement based on improved energy concentration in the plasma jet. High-precision plasma cutting enables higher cutting quality and lower heat input.

Dual-gas plasma cutting

In dual-gas plasma cutting, often referred to as plasma cutting with secondary gas, two different gases are used for the cutting process to achieve improved cutting quality. In dual-gas plasma cutting, one gas is used for the plasma jet itself, while a secondary gas is often used as a shielding gas or guiding gas. This cools the cutting surface and additionally removes material residues from the cut. For this reason, plasma cutting with secondary gas is particularly suitable for cutting stainless steel and aluminum, where minimal oxidation is desired.

Metal processing - Inquiry

Line Up: Start your procurement process now

Make an inquiry

Receive offer

Place order

Receive products

Other manufacturing processes of metal processing

Realize your products with the metal processing of Line Up

Contact

Ready to Line Up?

Contact us!

Personally there for you throughout Europe and in China. When will you become one of our satisfied customers?