Focus: Acceptable quality level (AQL)

Reading Time: 7 min.

In the world of manufacturing and quality assurance, the AQL value, or Acceptable Quality Level, is a crucial beacon that points the way to product trustworthiness and safety. But what exactly is behind this term and how can you use it to ensure the quality of your products? This blog post dives deep into the topic of AQL and explains how AQL charts, AQL tables and AQL sampling are used in quality management.

What is the AQL value?

The AQL value stands for Acceptable Quality Level. It defines the maximum number of defects that can be tolerated in a production batch in order to be considered acceptable. This measure is used in particular where high quality standards are essential.

In the application of the AQL (Acceptable Quality Level) system, there are two main tables that are used to assess the quality of a batch. These two tables are:

AQL Sample Size Table

Acceptance and Rejection Table

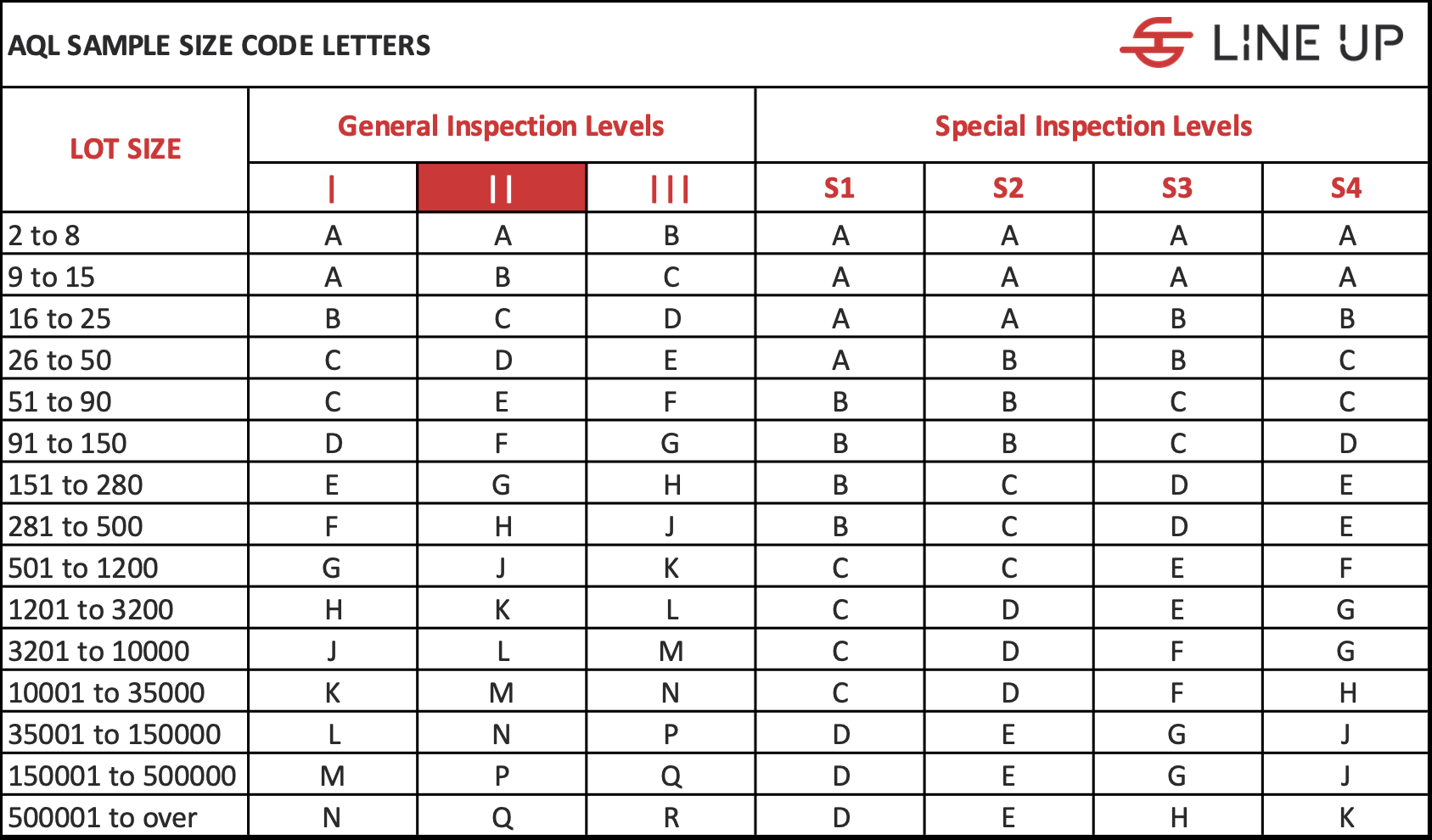

AQL sample size table (Table 1)

This table is used to determine the sample size required to inspect the entire batch. The process is as follows:

Determine the level of inspection: first select an inspection level, which is often dependent on the importance of the product and the risk. Level II is often used for general inspections.

Selecting the code letter: A code letter is determined from the sample size table based on the total number of units in the batch and the selected inspection level.

Determining the sample size: This code letter refers to the corresponding sample size to be inspected in the batch.

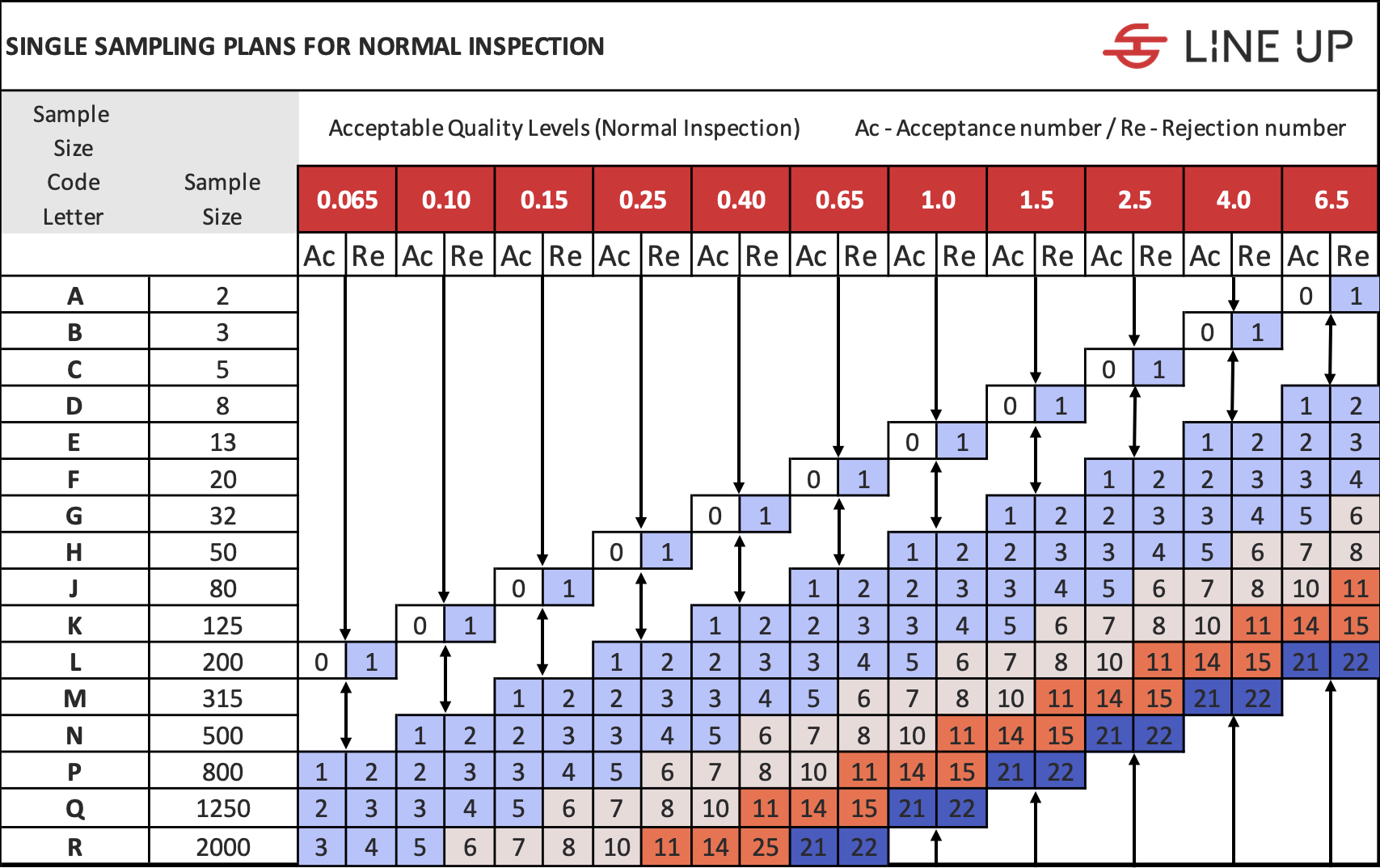

AQL acceptance and rejection table (Table 2)

Once the sample size has been determined, the acceptance and rejection table is used to determine how many errors are tolerable within the sample.

Determining the AQL value: First, the AQL value is determined, which indicates the maximum number of defects that can still be tolerated in the sample in order to accept the batch.

Using the code letter: The previously determined code letter is used to find the acceptance and rejection numbers in the table.

Determining acceptance and rejection numbers: The table indicates how many units in the sample may be faulty (acceptance number) and the number of faults above which the batch is rejected (rejection number).

Example of the application of the Acceptable Quality Level (AQL)

Let's assume you have a batch of 8,000 units and select Level II for the inspection. From the AQL sample size table (Table 1), the code letter "L" results for your batch size. This letter refers to an AQL sample size of 200 units in the AQL acceptance and rejection table (Table 2).

With an AQL of 1.5, go to the acceptance and rejection table and look for the code letter "L". There you will find the corresponding acceptance and rejection figures for this AQL value. In this example, this corresponds to an acceptance number of 7 and a rejection number of 8, which means that of the 200 units checked, up to 7 faults can be accepted. If you find 8 or more errors, the entire batch will be rejected.

This two-stage method of AQL tables allows quality assurance to be carried out efficiently and systematically, which plays an important role in the quality management of any manufacturing company.a

AQL in quality management

In the context of quality management, the AQL value is an important tool for monitoring and controlling the quality of processes and products. It helps to define quality targets, optimize production and increase customer satisfaction. An effective AQL system helps companies to find the balance between quality and costs while minimizing the risk of quality problems.

FAQ: Frequently asked questions about AQL

What does a lower AQL value mean for my production?

A lower AQL value indicates stricter quality requirements as it allows for a lower number of defects within your sample. This can lead to higher quality standards for your products, but may require more intensive quality control measures.

Can the AQL value vary by industry?

Yes, the AQL value can vary depending on the industry and type of product. In industries where safety and reliability are critical, such as the medical and pharmaceutical industries, lower AQL values are typically set.

How often should the AQL test be carried out?

The frequency of AQL testing depends on several factors, including consistency of product quality, production volumes and historical quality data. A regular testing schedule helps to monitor and improve quality over time.

AQL: The path to excellent product quality

The AQL value, together with AQL charts, tables and sampling, is an indispensable tool in quality management. It enables companies to organize their quality control processes efficiently and effectively by providing a clear guideline of how many defects are acceptable within a production lot. By using the AQL system, companies can not only ensure the quality of their products, but also gain and maintain the trust of their customers.

Do you have questions about the AQL value or need support in implementing an AQL system in your company? Contact us - our team of experts will be happy to assist you on the path to quality assurance.

Newsletter Registration

Sign up now for our free Line Up newsletter and stay up to date.