Table of Contents

- CNC manufacturing: Maximum precision for series production

- What is CNC manufacturing?

- CNC processes at a glance

- Why is CNC manufacturing ideal for series production?

- 7 advantages of CNC manufacturing

- Typical areas of application for CNC manufacturing

- Which trends characterise precision manufacturing

- Preparing for the future with CNC manufacturing

CNC manufacturing in series production

Reading Time: 5 min.

CNC manufacturing: Maximum precision for series production

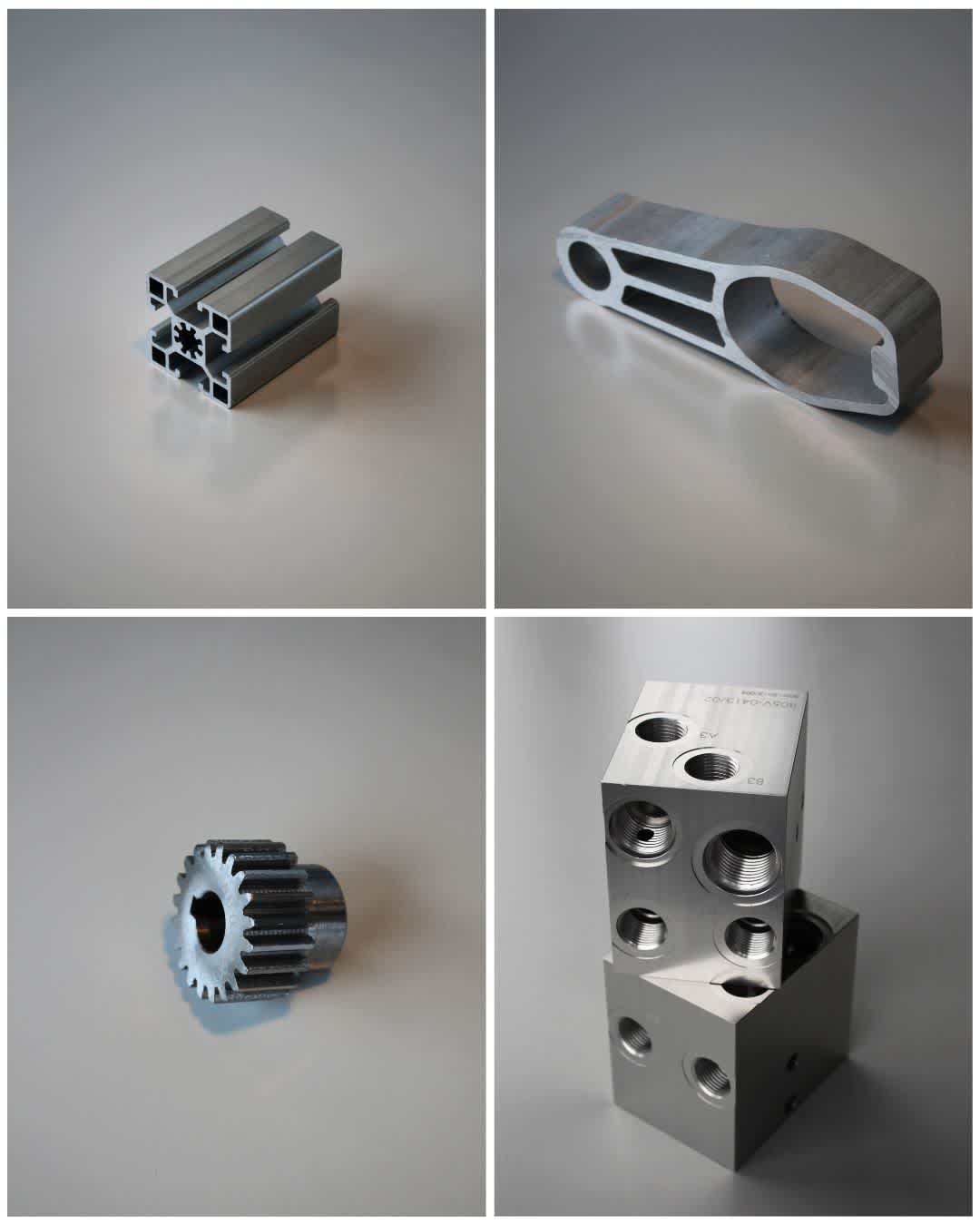

Precision is the key word in modern series production. Companies that produce complex components in large quantities are increasingly turning to CNC. We reveal which CNC processes are available and what advantages they offer.

What is CNC manufacturing?

CNC (Computerised Numerical Control) manufacturing is a modern manufacturing process that uses computer-controlled machines to precisely machine workpieces. The process usually begins with a digital design in the form of a CAD (Computer Aided Design) file. This file is converted into a CNC programme that precisely specifies the movements and processing steps of the machine.

During machining, the material is then removed from a blank to create the desired shape. CNC manufacturing therefore enables milling, turning and drilling processes to be carried out with a precision that far surpasses manual processes.

The advantages are obvious: CNC machining offers a combination of efficiency, flexibility and repeatability that is unrivalled in traditional manufacturing processes. Thanks to its versatility, it is suitable for the production of both prototypes and large series.

CNC processes at a glance

CNC milling

CNC milling is a versatile process in which rotating tools precisely remove the material. Depending on the machining task, different milling tools such as end mills, face mills or ball nose end mills are used. Their movement along several axes creates complex geometries and fine surfaces.

High flexibility for complex components

Precise contours and fine surfaces

Use for different materials and tasks

CNC turning

CNC turning is ideal for cylindrical components. Here, the workpiece rotates around its own axis while stationary tools remove the material. It enables both simple turning operations and specialised tasks such as thread cutting.

Efficient for rotationally symmetrical workpieces

High surface quality

Flexibility due to varying turning tools

CNC drilling

CNC drilling enables the precise production of holes. A rotating twist drill creates cylindrical openings, while countersinks or reamers improve the surface quality and deburr edges.

High accuracy and repeatability

Flexibility with different hole qualities

Essential for compliance with strict tolerances

Why is CNC manufacturing ideal for series production?

With its focus on precision, efficiency, flexibility and cost benefits, CNC manufacturing offers you the opportunity to produce high-quality products in large quantities. The following features are particularly impressive in series production.

Precision

CNC machines guarantee maximum precision and reproduce complex components exactly - even with large quantities, the quality remains constant.

Efficiency

Automated processes reduce processing times and speed up production, which saves resources and cuts costs.

Flexibility

CNC controls can be quickly and easily adapted to modified designs or new product specifications.

Cost benefits

The high level of automation minimises errors, reduces waste and makes production more cost-efficient overall.

7 advantages of CNC manufacturing

1. easy quality assurance

CNC machines work with the highest precision and ensure that every component corresponds exactly to the specifications. Regular quality checks can be easily integrated into the process.

2. increased scalability

Regardless of whether small batches or large production volumes are involved - CNC machines adapt easily to different quantities.

3. wide variety of materials

From metals such as aluminium and stainless steel to plastics - CNC manufacturing is ideal for numerous materials.

4. more sustainability

Precise material processing produces less waste, which reduces costs and protects the environment.

5. optimised supply chain

CNC manufacturing enables just-in-time production, which streamlines delivery processes and reduces storage costs.

6. better competitiveness

Thanks to the increased flexibility, companies can react more quickly to market requirements with CNC manufacturing and realise innovative products.

7. high level of reliability

CNC machines work around the clock and guarantee consistent production quality.

Typical areas of application for CNC manufacturing

CNC manufacturing has established itself as an indispensable technology in numerous industries. It plays a key role in the automotive industry in particular, where it is used to manufacture precise and resilient engine components, gearboxes and body parts.

CNC manufacturing is also indispensable in medical technology: it enables the production of implants, surgical instruments and other medical devices where exact dimensions and flawless surface quality are crucial.

In the aerospace industry, CNC manufacturing ensures the production of components that fulfil extreme requirements in terms of stability and weight. Companies in the logistics and procurement sector also benefit from the technology, as it produces machine components that are essential for a smooth supply chain.

Which trends characterise precision manufacturing

CNC manufacturing is constantly evolving. New technologies and approaches ensure that precision machining becomes even more accurate, efficient and sustainable. Automation, which enables the seamless integration of CNC machines into Industry 4.0 processes and the efficient combination of different manufacturing technologies, is particularly noteworthy.

AI is also playing an increasingly important role: intelligent CNC controls can analyse and optimise machining processes in real time, making the manufacturing process even more precise. At the same time, energy-efficient CNC machines and sustainable processes significantly reduce the environmental impact.

The following applies for the future: companies that adapt these trends at an early stage can not only gain a competitive advantage, but also lay the foundations for sustainable growth in an increasingly digitalised manufacturing world.

Preparing for the future with CNC manufacturing

CNC manufacturing combines precision, efficiency and flexibility in a unique way. In series production in particular, it impresses with its consistently high quality, reduced costs and impressive versatility. If you want to integrate various CNC processes into your manufacturing processes, you can create a solid foundation for future-proof and competitive production structures.

Would you like to find out more about how CNC manufacturing can boost your production? Let's optimise your precision manufacturing together - our experts at Line Up develop individual solutions that will take your production to the next level.

Simply get in touch with us using our contact form.

Newsletter Registration

Sign up now for our free Line Up newsletter and stay up to date.