Table of Contents

- What is logistics 4.0?

- Advantages of digitalised logistics:

- Which technologies are shaping the logistics industry

- Autonomously ahead: drones, self-driving ships and lorries

- What opportunities does the digitalisation of logistics offer?

- 3 key challenges that need to be overcome

- Digitalisation in logistics: where is the journey heading?

Digitalisation in the logistics industry

Reading Time: 7 min.

AI, big data, cyber-physical systems, automation, Internet of Things & Co.: How does digitalisation work in logistics? Which trends and topics are hotly debated? And what opportunities and challenges will the logistics industry face?

The logistics industry is undergoing unprecedented change: according to a study conducted by the German Logistics Association (BVL) in 2023, the so-called triple transformation - consisting of digitalisation, resilience and sustainability - is one of the biggest trends in the industry. The aim of ‘Logistics 4.0’ is to optimise supply chains, increase efficiency and ensure greater transparency.

What is logistics 4.0?

The terms Logistics 4.0 or Supply Chain 4.0 describe the shift towards a fully automated, networked and data-driven logistics world in which data is recorded, processed and used to control the entire supply chain in real time.

This is a comprehensive approach to the digitalisation and automation of the entire logistics chain. The aim is to use cyber-physical systems (CPS), the Internet of Things (IoT) and other technologies to create closer networking between machines, goods and people. This enables physical and digital processes to communicate seamlessly with each other, thus ensuring greater transparency, efficiency and flexibility.

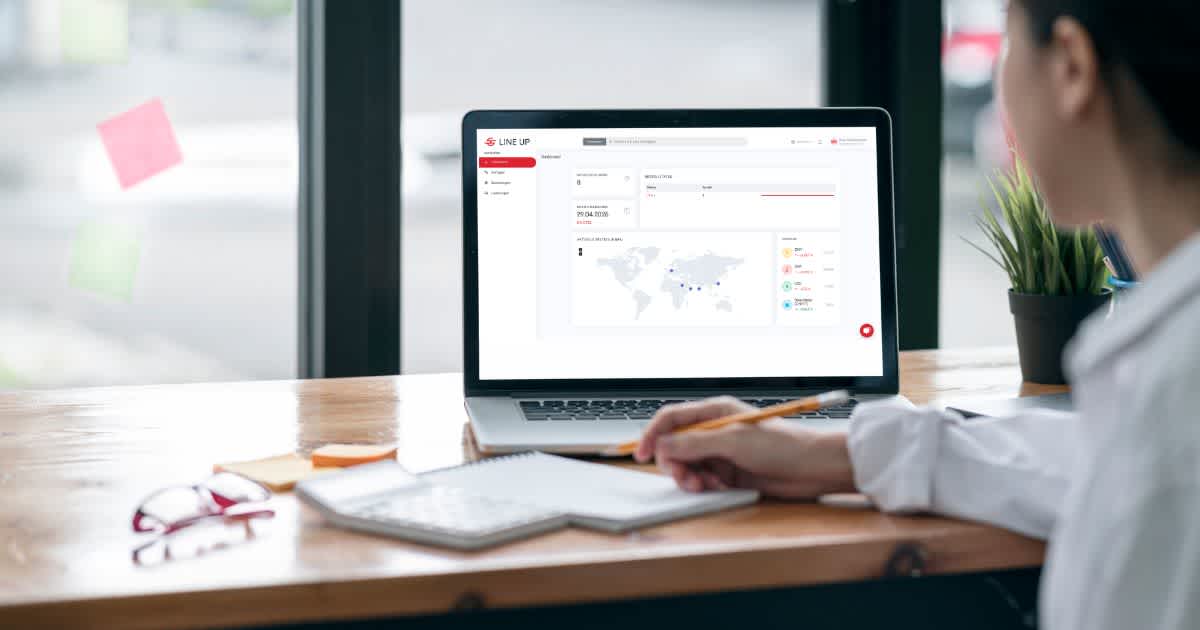

For example, the use of sensors and RFID tags allows the flow of goods to be monitored in real time. Platforms such as the Line Up Supply Chain Dashboard then enable the exchange of this information between manufacturers, suppliers and logistics service providers, leading to optimised route planning and reduced storage costs.

Advantages of digitalised logistics:

Increased efficiency: Progressive process automation and networked systems improve efficiency by allowing AI and robots to take over tasks such as route planning and routine work.

Greater transparency: IoT and big data enable real-time monitoring of supply chains, resulting in seamless transparency and faster response options.

Greater flexibility: Data-based systems ensure flexible adjustment of stock levels and transport capacities, allowing companies to react more agilely to market changes and unforeseen events.

Cost reductions: Optimised route planning, reduced storage costs and the use of semi-autonomous technologies contribute to a significant reduction in logistics costs.

Sustainability: Optimised routes and the avoidance of empty runs help to reduce emissions and use resources more efficiently.

Greater reliability: Improved automation and digitalisation reduce delivery bottlenecks and increase the reliability of the supply chain.

Reduced susceptibility to errors: Automated systems minimise human error and improve accuracy.

Reduced storage costs: Optimised inventory management and efficient transport planning reduce storage and logistics costs.

Which technologies are shaping the logistics industry

The digitalisation of logistics is based on a variety of innovative technologies that are used along the entire supply chain. They make it possible to make processes more efficient, transparent and flexible in order to meet the requirements of modern logistics chains.

Driverless transport systems

So-called AGV (Automated Guided Vehicles) systems take over the transport of goods within warehouses or between logistics centres and reduce manual intervention.

Robotics

Automated robots can perform tasks such as loading and unloading goods or order picking quickly and precisely.

Artificial intelligence (AI)

AI applications improve the prediction of demand and stock levels and enable optimised route planning.

Cyber-Physical-Systems

Cyber-physical systems combine physical processes with digital control and enable machines and systems to communicate and interact with each other in real time.

RFID (Radio-Frequency-Identification)

RFID technology makes it possible to track the flow of goods and monitor stocks in real time.

Big Data

The automated analysis of large volumes of data allows logistics processes to be continuously optimised, planned with foresight and bottlenecks to be avoided.

Platform economy

Digital platforms connect manufacturers, suppliers and logistics service providers with each other, creating the basis for more efficient collaboration and more transparent supply chains.

Blockchain

Blockchain technologies ensure forgery-proof documentation of deliveries and contracts, which is particularly important in the area of product traceability.

Internet of Things (IoT)

Networked devices and sensors collect real-time data on the condition of goods, vehicles and machines, resulting in more proactive maintenance and smoother operations.

Autonomously ahead: drones, self-driving ships and lorries

Large logistics providers such as Amazon are already testing the use of drones, which are particularly interesting for small and time-critical deliveries. Drones are primarily being tested in last-mile delivery, i.e. the delivery of goods over the last few kilometres to the end customer. The major advantage lies in the ability to deliver parcels quickly and efficiently, even to areas that are difficult to access or urban areas with high traffic volumes delivery.

Autonomous lorries also offer enormous potential for logistics. They can cover longer distances without driver breaks, significantly reduce transport costs and also alleviate the shortage of skilled labour. Pilot projects are already underway in the USA and Europe that show that autonomous lorries could play a key role in long-distance transport in the future.

Autonomous ships also promise to make sea freight more efficient and cost-effective by being able to travel long distances without a crew. Companies such as Rolls-Royce are already working on corresponding concepts that could have a lasting impact on global maritime logistics in the coming years. Autonomous vehicles are good examples of the far-reaching technological change that is revolutionising the logistics industry.

What opportunities does the digitalisation of logistics offer?

One of the biggest advantages of digitalised logistics lies in the optimised supply chain: by using digital technologies, companies can plan ahead, reducing the susceptibility to errors and making processes run more smoothly. This leads to better resource allocation, which represents a significant competitive advantage, especially in complex, global supply chains.

In addition, digitalisation enables much closer collaboration between manufacturers, suppliers and logistics service providers. Data integration platforms simplify the exchange of information, improve transparency and ensure that all parties involved can access important data in real time.

Another key benefit is the reduction in freight costs when automated systems and optimised route planning ensure that vehicles are used more efficiently and unnecessary journeys are avoided. This not only leads to cost savings, but also has a positive impact on sustainability by reducing emissions. Digital technologies also make it easier to enter international markets by simplifying cross-border logistics processes and increasing global competitiveness.

3 key challenges that need to be overcome

1. sustainability vs. economic efficiency

A key difficulty lies in the balancing act between sustainability and economic efficiency: companies increasingly see it as their duty to achieve their ecological goals without jeopardising economic efficiency. And sustainable solutions, such as low-emission transport methods or energy-efficient technologies, are often associated with higher costs, which requires a careful balance between environmental protection and competitiveness.

2. data protection and cybersecurity

With the increasing networking of systems, the risk of cyber attacks is also increasing. Companies must ensure that their sensitive data - as well as that of their partners and customers - is protected against unauthorised access. However, implementing comprehensive security measures is often cost-intensive and requires specialised expertise.

3. human-machine collaboration

While automated systems take over routine tasks and increase efficiency through the use of real-time data, people remain indispensable when it comes to strategic decisions and creative problem-solving. The challenge lies in integrating collaborative technologies in such a way that they support rather than replace human labour.

Digitalisation in logistics: where is the journey heading?

As you can see: Digitalisation in logistics offers numerous opportunities that enable companies to optimise their processes, reduce costs and make supply chains more sustainable.

One thing is clear: the future of logistics will be characterised by collaboration between people, machines and innovative technologies, and companies that drive the transformation process forward now will be ahead in the long term.

We support you: with expert advice, comprehensive procurement services and the Line up Supply Chain Dashboard, which can digitally map the entire supply chain.

Simply contact us using our contact form.

Newsletter Registration

Sign up now for our free Line Up newsletter and stay up to date.