Make-or-buy: in-house production or outsourcing?

Reading Time: 3 min.

The make-or-buy decision is one of the central strategic cornerstones of a company. This raises the question: should a product or service be manufactured internally (in-house production) or procured externally (external procurement)? The decision not only influences the cost structure, but also quality, flexibility and competitiveness.

A well-founded make-or-buy analysis helps to objectively weigh up the opportunities and risks. This article highlights the most important decision-making factors, calculation methods and strategic considerations to help companies choose the optimal production strategy.

What is a make-or-buy decision?

A make-or-buy decision involves weighing up internal production (make) and external procurement (buy). Business, strategic and technological factors play a role here. The decision can concern individual components, entire production processes or even services.

In-house production (Make)

With in-house production, the company takes over the production of a product or service itself. This requires investment in machinery, personnel and know-how. Companies therefore have complete control over the manufacturing process, which enables smooth coordination with internal processes. The vertical range of manufacture also plays a decisive role: the more production steps are covered internally, the greater the influence on quality and processes.

External procurement (Buy)

With external procurement, the manufacture of a product or service is outsourced to external suppliers. Companies purchase finished components or complete end products instead of producing them themselves. This strategy can extend to individual components as well as entire production processes. The decisive factor here is the selection of suitable suppliers that meet the desired quality and cost requirements.

Advantages of in-house production

In-house production has several advantages:

Quality control: the company can set and monitor its own standards.

Flexibility: Quick adaptation to market changes and customer requirements.

Long-term cost savings: Despite high initial investments, economies of scale can be utilized.

Advantages of external procurement

Outsourcing also has strategic and economic advantages:

Cost efficiency: external providers benefit from economies of scale and lower fixed costs.

Focus on core competencies: The company can concentrate on strategically important areas.

Faster implementation: products or services are often available at short notice.

Lower investment risk: No high initial costs for machinery or infrastructure.

Decision-making factors for make-or-buy

The make-or-buy analysis comprises various criteria that enable a well-founded decision to be made:

Cost analysis: calculation of all costs incurred for in-house production vs. external procurement.

Capacities: Availability of internal resources such as machinery, personnel and know-how.

Quality requirements: Possibility of ensuring the desired quality.

Strategic importance: Influence of the decision on competitiveness.

Risk assessment: Possible dependencies on suppliers or technical challenges.

The make-or-buy calculation

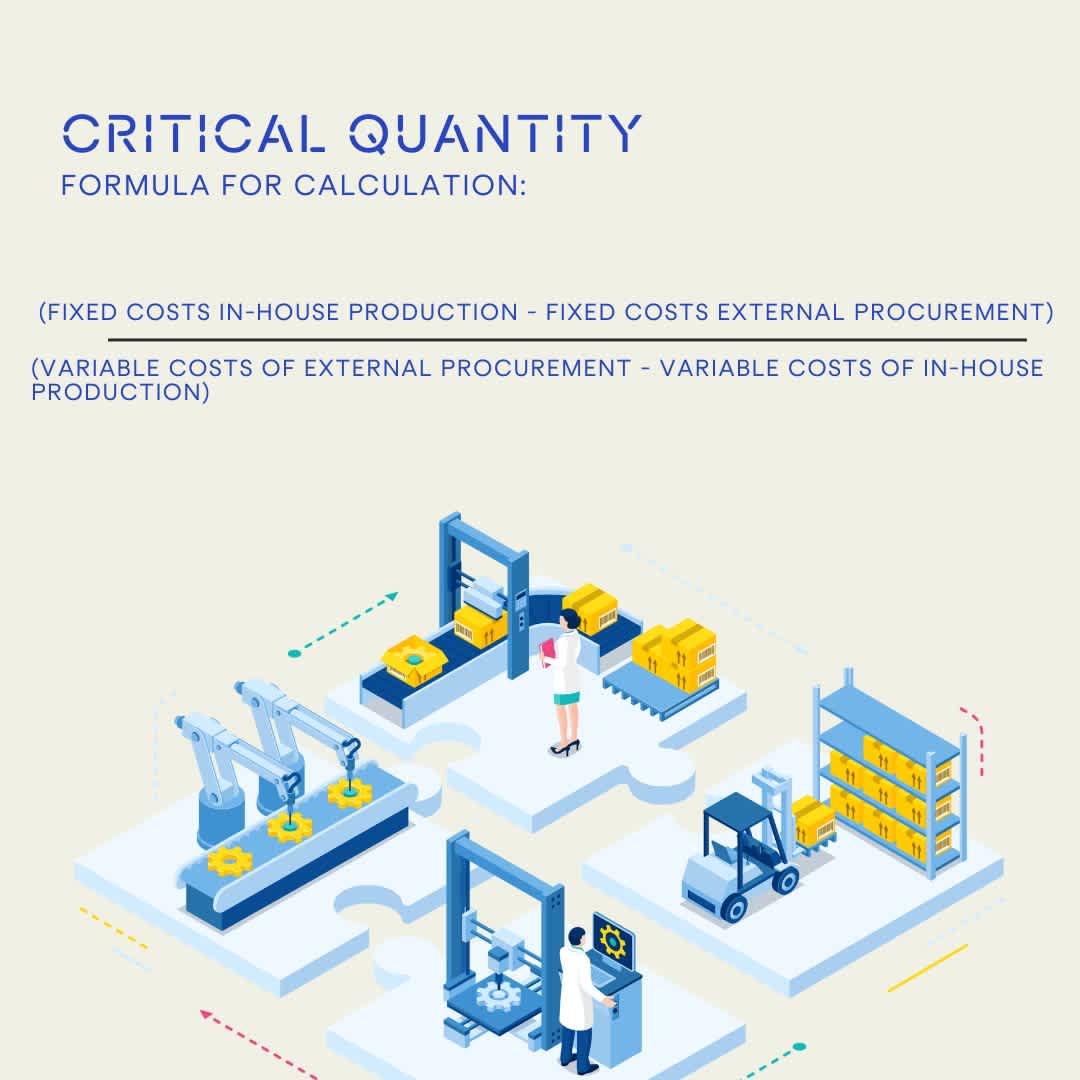

The make-or-buy calculation provides a quantitative basis for decision-making. This involves determining the total fixed and variable costs for in-house production and external procurement. The formula for determining the critical production quantity is:

If the production quantity is above this limit, in-house production is worthwhile. If it is below this limit, it is more advantageous to outsource.

Strategic decision: Insourcing or outsourcing?

The choice of production strategy depends on various factors, including costs, flexibility and strategic orientation. Insourcing can make sense if companies have special requirements in terms of quality and expertise or want to control sensitive processes internally. Outsourcing, on the other hand, provides access to external expertise, increases efficiency and can help to optimize costs. It also offers companies the opportunity to focus more on their core competencies and react flexibly to market changes. Which strategy is the right one depends on the individual company goals and framework conditions.

Conclusion: Make or buy - what is the right choice?

The decision between in-house production and external procurement requires a thorough analysis. In addition to costs, factors such as quality, flexibility and strategic orientation play a decisive role. A make-or-buy analysis helps companies to find the most economically viable solution.

Companies wishing to optimize their manufacturing or procurement strategy benefit from professional advice and market expertise. Line Up supports companies in developing efficient production and procurement strategies in order to secure long-term competitive advantages. From supplier research to strategic purchasing advice, Line Up offers comprehensive solutions to find the optimal balance between in-house production and external procurement.

Newsletter Registration

Sign up now for our free Line Up newsletter and stay up to date.